Comparing Electric vs.Pneumatic Power Tools: What Works Best in Dubai?

In the realm of construction and industrial projects, the choice between electric and pneumatic power tools often determines the efficiency and success of the job. Dubai, a bustling hub of construction and development, presents a unique landscape where the selection of the right tools is paramount. In this article, we delve into the comparison between electric and pneumatic power tools, exploring their pros and cons in the context of Dubai’s working environment. When it comes to power tools, the debate between electric and pneumatic variants has been ongoing for decades. Each type boasts its own set of advantages and limitations, making the decision-making process a crucial one, particularly in dynamic environments like Dubai. Let’s explore the key factors that influence the effectiveness of electric and pneumatic power tools in this vibrant city.

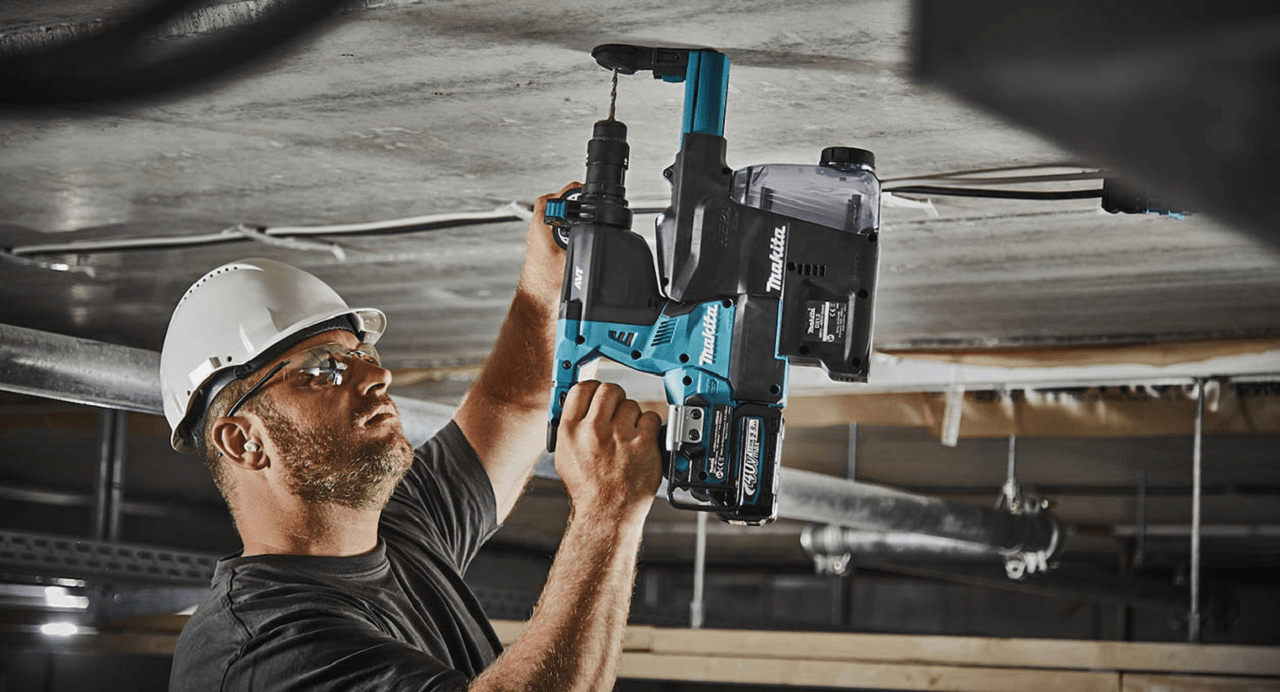

Electric Power Tools

Electric power tools rely on electricity to function, making them convenient and versatile for various applications. In Dubai, where power sources are abundant, electric tools are widely used across construction sites and workshops. These tools include drills, saws, grinders, and sanders, offering a broad range of functionalities to cater to different project requirements.

You will be interested on: Hardware Stores in International City

Advantages of Electric Power Tools

Ease of Use: Electric power tools are user-friendly and require minimal setup. With a simple plug-and-play mechanism, workers can swiftly get started on their tasks, enhancing overall productivity.

Portability: Cordless electric tools provide mobility, allowing workers to move freely around job sites without being tethered to a power source. This is particularly advantageous in Dubai’s expansive construction projects.

Powerful Performance: Electric tools deliver consistent power output, ensuring efficient operation even in demanding conditions. This reliability is crucial for meeting tight deadlines and maintaining quality standards.

Disadvantages of Electric Power Tools

Dependency on Electricity: Despite their portability, cordless electric tools rely on battery power, which may run out during extended use. This necessitates spare batteries or access to charging stations, which may not always be readily available.

Limited Durability: Electric tools are prone to wear and tear, especially in harsh environments like construction sites. Over time, components such as motors and switches may degrade, requiring frequent maintenance or replacement.

Keep Reading on: Hardware Stores in Ras Al Khor Road

Pneumatic Power Tools

Pneumatic power tools, also known as air tools, utilize compressed air to generate force, making them robust and reliable in industrial settings. While they require an air compressor to operate, pneumatic tools offer unparalleled performance in terms of power and endurance, making them a preferred choice for certain applications in Dubai.

Advantages of Pneumatic Power Tools

High Power Output: Pneumatic tools are known for their exceptional power-to-weight ratio, allowing for efficient handling of heavy-duty tasks such as drilling, riveting, and bolting. In Dubai’s construction projects, where strength and precision are paramount, pneumatic tools excel.

Durable Construction: Unlike electric tools, pneumatic counterparts have fewer moving parts, reducing the likelihood of mechanical failures. This inherent durability ensures longevity, minimizing downtime and maintenance costs.

Consistent Performance: Pneumatic tools operate at a constant power level, unaffected by fluctuations in voltage or temperature. This consistency is invaluable in Dubai’s climate, where extreme heat can compromise the performance of electric tools.

You will be interested on: Hardware Stores in Riggat Al Buteen

Disadvantages of Pneumatic Power Tools

Dependency on Air Supply: Pneumatic tools rely on a continuous supply of compressed air, necessitating the presence of an air compressor on-site. In Dubai, where power outages are rare but not impossible, a reliable source of compressed air is essential for uninterrupted workflow.

Limited Mobility: Unlike cordless electric tools, pneumatic tools are tethered to an air hose, restricting movement to the vicinity of the compressor. This can be cumbersome in large-scale projects where mobility is a priority.

Conclusion

In the dynamic landscape of Dubai’s construction industry, the choice between electric and pneumatic power tools depends on various factors, including the nature of the project, environmental conditions, and budget constraints. While electric tools offer convenience and versatility, pneumatic counterparts excel in terms of power and durability. Ultimately, the decision boils down to striking a balance between efficiency, reliability, and practicality to ensure the successful completion of projects in Dubai’s ever-evolving skyline. By carefully weighing the pros and cons of each option, contractors and workers can optimize their tool selection to meet the unique demands of this vibrant city.