Buy Welding Items in Dubai at Wholesale Price from SAFATCO

Beginners may find welding to be a somewhat intimidating endeavour.

It requires so many tools, and you will be exposed to so much heat and so many pressurised components, that the threat may appear overwhelming.

However, there is no reason for alarm. Here is a list of the best welding equipment for novices to learn the trade swiftly and safely.

1. Auto-Darkening Welding Helmet

- The welding helmet is the most fundamental and well-known piece of welding equipment available. It is also a safety necessity.

- The basic function of any form of welding helmet is to shield your face from sparks and flames while you work and to protect your skin and eyes from the heat.

- Auto-darkening helmets provide the added benefit of shielding the wearer’s eyes from the intense light emitted by other welding equipment as well as the molten metal itself.

- The glass covering the eyes is tinted to allow just a certain quantity of light through at once, allowing you to see without causing damage to your eyes.

2. Welding Gloves

Gloves require little explanation. The layers of durable textiles and insulation in welding gloves protect harm from heat and stray sparks. Welding gloves are readily available anywhere gloves are sold, and they are needed for all types of welding.

There are typically two sorts to be aware of;

- MIG Welding gloves are often thicker and contain padding on the back of the hand to protect the hand that is resting while the dominant hand braces during a weld. If the gloves become too warm, the looser fit allows you to effortlessly remove them.

- TIG Welding Gloves — These gloves are thinner and softer, allowing for more precision. When TIG welding, dexterity is essential, so the gloves will fit more snugly to allow for accurate movement while holding the rod and flame.

Ensure that you have the appropriate gloves for the work.

3. MIG Welding Pliers

MIG pliers are accessible at the majority of hardware stores and online. They are not a speciality item and are rather inexpensive given their versatility.

They have several uses which include:

- They are furnished with circular clamps, which are ideal for removing nozzles from MIG guns.

- Loosen and tighten the contact tip on a regular basis, as it will become worn with time.

- Cut 1/4-Inch Stick-Out – Saves time over using a separate wire cutter.

- Remove Weld Spatter – The tips of the pliers make it easy to clean spatter from the inside of the nozzle.

If you own a MIG welder, a pair of excellent MIG pliers is vital.

4. Welding Magnets

- Magnets for welding are one of the most versatile instruments you will possess. This is why they are so handy for welding.

- With a welding magnet, metal components can be held in place without the use of clamps and readily manipulated.

- Additionally, they allow you to mount metal components and solder them at an angle.

- In short, they enable the welding of sheet metal pieces in ways that clamps would not permit. The longer you employ these, the more applications you will discover.

5. Chipping Hammer

- The condensation of slag as the metal melts and produces the weld is a characteristic of MIG welding and stick welding.

- Sometimes, this slag must be scraped away. This is the purpose of the chipping hammer.

- Chipping hammers have a flat side and a pointed side, each of which is ideal for a specific type of slag.

- These may not be utilised frequently, but they make the welding process considerably cleaner and more manageable.

6. Welding Framing Jig

- A welding frame jig is not as essential as many of the other items on our list, but it is still a useful tool to have.

- A framing jig for welding provides a device for welding at 90-degree angles. While a welding magnet could be used for this, a frame jig provides a considerably higher level of support during welding and permits the use of larger metal parts.

- Unlike magnets, it also permits the simultaneous tack welding of numerous layers or multiple components at a precise 90-degree angle.

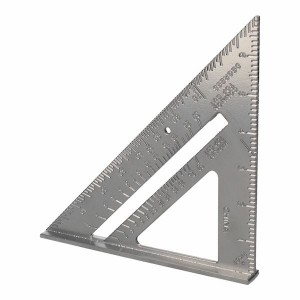

7. Speed Square

- A speed square may be the tool you utilise the most out of all those described. With your speed square, you may measure any item parallel to another for a 90-degree cut or at any other angle.

- A speed square is an angular measuring instrument in the shape of a right triangle that permits several types of measurement at different angles. Among all the available welding equipment, this is the one you will reach for most frequently. You cannot accomplish much without measurement.

8. Metal Brush

- Similar to a chipping hammer, a metal brush is a tool that is rarely considered but is utilised frequently during welding.

- A metal brush eliminates slag and charring from the surface of cooled welds, leaving the surface spotless.

- Not all welding processes produce slag, but those that do require the use of both chipping hammers and metal brushes for optimal completion.

9. Angle Grinder

- If you frequently weld, an angle grinder might be a very valuable addition to your toolbox.

- First, it can cut through metal. There will always be a requirement to cut down metal stock. With a cut wheel, anything from sheet metal to bar material may be cut with surprising simplicity.

- Angle grinders can also be used to prepare metal prior to welding. To prevent flaws like as porosity and cracking, you must clean the base metal. This can be accomplished with a wire brush, but an angle grinder will save you a great deal of time.

- Finally, a welding angle grinder is an excellent tool for finishing and cleaning welds. When there is a large amount of leftover slag, an angle grinder can be used to effectively remove it. Also, if you need to polish the metal you are working with, you can do so with an angle grinder!

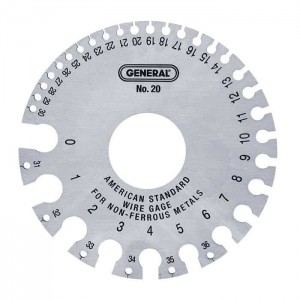

10. Sheet Metal Gauge

- To successfully weld, you must know the thickness of the metal you are working with.

- A steel metal gauge is a wheel with teeth whose spacing corresponds to the various standard widths of sheet metal.

- The sheet metal gauge is a useful instrument for welders of all skill levels.

- Knowing the thickness of the sheet metal you will be dealing with can impact many other aspects of your project.

- Most skilled welders have a chart that specifies the settings to use for each sheet metal thickness.

- Additionally, it can be difficult to discern one piece of sheet metal from another based on appearance alone, therefore the gauge will be necessary.

11. Soapstone

- Although soapstone is not composed of soap, its marking tool has a comparable consistency.

- Soapstone is used as a marking tool that is easily removable after use. Consider it to be chalk designed specifically for writing on metal.

- Soapstone is preferable than graphite because it can survive high temperatures and the attack of flames from torches and other welding equipment.

- In addition to writing directly on the metal, it also lets you to draw intricate curves, curved lines, and other motifs.

12. Metal File

- Similar to the angle grinder, the principal function of the metal file is to smooth rough edges and burrs from cut metal.

- You’ve probably used metal files before for a variety of other metalworking tasks.

- While angular grinders excel at the harsher removal process, files are utilised for polishing and beautifying a finished product.

13. C Clamp

- C clamps have the appearance of the letter C.

- They can simultaneously apply pressure from above and below and are commonly used for a wide range of hardware projects, not simply welding.

- C clamps also permit a greater level of pressure than pinch clamps or even some welding clamps, allowing for a considerably more secure grasp on the object being clamped.

14. Welding Boots

Foot injuries are among the most prevalent and least discussed occupational accidents. An estimated 25 percent of all disability claims are the consequence of work-related foot injuries.

Foot injuries are among the most prevalent and least discussed occupational accidents. An estimated 25 percent of all disability claims are the consequence of work-related foot injuries.

- With this information in mind, you should protect your feet from the hot metal and heavy equipment you will be using when welding.

- Any welder’s footwear must be as durable as possible. Leather uppers and steel-reinforced toes are required. The intention is to protect your feet from falling molten metal.

15. Welding Cart

- The welding cart is less a tool than a way of transporting other tools.

- Air tanks are cumbersome. Fans are massive. Tanks for fuel are heavy.

- A welding cart makes it easier and more efficient to move all of these items. Some welding carts include toolboxes, providing a convenient location for the other items on this list.

16. Welding Sleeves

- Welding sleeves are similar to welding boots in that they are essential for your safety while welding yet are rarely discussed.

- Welding sleeves are detachable sleeves, typically made of leather or another non-combustible and durable material, that protect your clothing and skin from injury.

- The majority of welding sleeves are attached to an apron or have suspenders to keep them in place. Others resemble a woman’s crop top, with a collar and partial chest linked to the sleeves for increased comfort and safety.

- When flying sparks of flaming metal are present, the last thing you want is for your shirt to catch fire, therefore more coverage is always preferable.

17. Safety Glasses

- You cannot always wear a welding helmet, and it can be excessive at times.

- A pair of dependable safety glasses is ideal for situations like these.

- Safety glasses are made of tough plastic and prevent sparks from an angle grinder from entering the wearer’s eyes.

18. MIG Welding Nozzle Gel

- Gel near the tip of the nozzle is another crucial aspect of welding that is sometimes disregarded. Nozzle gel prevents the torch’s metal nozzle from adhering to the metal being welded.

- As simple as it may appear to avoid this dilemma, it is always preferable to err on the side of caution. The proximity of a welding gun with a finer tip to the metal being welded may further demonstrate the necessity of this product.

- Nozzle gel can be applied to the nozzle of your torch or welding gun as easy as wax. As you work, it will warm and transform into a more liquid coating, keeping a barrier between the two metal surfaces and preventing adhesion.

Tags : Welding Equipment Suppliers in Dubai, Safety Materials Dubai, Adhesive Lubricants in Dubai, Tool Accessories shop Dubai, Building Material Suppliers, Hardware Store Dubai, Hand Tools in Dubai, Paints dealers in Dubai, Bosch Powertools Dubai, Power Tool Dealers in Dubai, Dewalt Powertools Dubai, Stanley Powertools Dubai, Makita Powertools Dubai